Polyurethane Properties

The diverse properties of castable polyurethane make it the leading choice of engineers looking for long lasting materials for their high load, high stress environments. Polyurethane routinely outperforms plastic, rubber and steel in its overall ability to resist harsh environmental factors such as abrasion, heat, solvents, oil and acid. In addition, polyurethane‘s noise abatement ability makes it the preferred material in chain-drive designs, conveyor belt systems and assembly line environments. In today’s manufacturing environments where the cost of downtime is measured in thousands of dollars per hour, polyurethane’s incredible durability actually increases your company’s profitability.

This page includes detailed information on polyurethane properties.

Physical Properties Of Polyurethane

Typical Physical Properties of Compounds of Polyurethane

| Polyurethane Type | L42 | L100 | L167 | L315 |

| Hardness, Durometer Value (ASTM d676-59T) | 80A | 90A | 95A | 75D* |

| Specific Gravity | 1.07 | 1.10 | 1.13 | 1.21 |

| Tensile Strength, MPa (psi) (ASTM D412-61T) | 20.7 (3,000) | 31.0 (4,500) | 34.5 (5,000) | 62.0(9,000) |

| Elongation At Break, % (ASTM D412-61T) | 800 | 450 | 400 | 270 |

| 100% Modulus, MPa (psi) (ASTM D412-61T) | 2.8 (400) | 7.6(1,100) | 12.4(1,800) | 32.0(4,650) |

| Compression Set, % Method B (ASTM D395) Method A (ASTM D395)** | 45 – | 27 9 | 40 10 | – 10 |

| Resilience, % Rebound (Bashore) | – | 45 | 40 | 45 |

| Impact Resistance, Izod notched J/m (ft.lb./In) (ASTM D256) 24 Degrees C ( 75Degrees F) -40 Degrees C (-40 Degrees F) | Flexed – | Flexed – | Flexed – | 800.7(15) 58.7 (1.1) |

| Solenoid Brittle Temp., Degrees C (Degrees F) (ASTM D746-57) | Below -80 (Below -120) | Below -70 (Below-94) | Below -70) (Below -94) | -64 (-83) |

| Abrasion Index, NBS, % (ASTM D1630, Nat’l Bureau of Standards Abrader) | 110 | 175 | 400 | 435 |

| Tear Strength Split, kN/m (pli) (ASTM D470) | 12.2(70) | 13.1 (75) | 26.2 (150) | 192.2 (110) |

| * The D Scale is used to measure durometer hardness above 95A by Shore, Rex, or Wallace durometers. ** Measured at 9.3 MPa (1,350 psi) | ||||

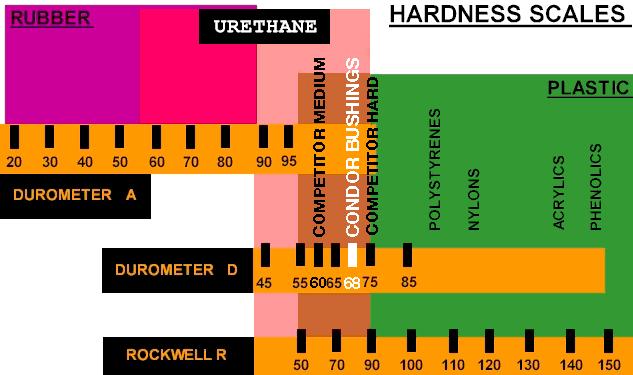

How Hard is Polyurethane?

The graphic on the left shows the relative hardness ratings available with polyurethane versus rubber and plastic. As you can see polyurethane is an extremely versatile substance. Best of all, polyurethane parts have longer service lives than those made from rubber and plastic.

Click On The Graphic For An Enlarged Image

The graphic on the left shows the relative hardness ratings available with polyurethane versus rubber and plastic. As you can see polyurethane is an extremely versatile substance. Best of all, polyurethane parts have longer service lives than those made from rubber and plastic.

Click On The Graphic For An Enlarged Image

Polyurethane Chemical Resistance

| Chemical | Rating | Chemical | Rating |

| A = EXCELLENT B = GOOD | |||

| Acetic Acid, 20% | B | Ammonium Hydroxide Solutions | A |

| ASTM Oil #1 (70°C/158°F) | A | ASTM Oil #3 (70°C/158°F) | B |

| ASTM Reference Fuel A | A | ASTM Reference Fuel B (50°C/122°F) | B |

| Barium Hydroxide Solutions | A | Borax Solutions | A |

| Boris Acid Solutions | A | Butane | A |

| Calcium Bisulfate Solutions | A | Calcium Chloride Solutions | A |

| Calcium Hydroxide Solutions | A | Carbon Dioxide | A |

| Carbon Monoxide | A | Castor Oil | A |

| Copper Chloride Solutions | A | Copper Sulfate Solutions | A |

| Cottonseed Oil | A | Cyclohexane | A |

| DOWTHERM A | B | Ethylene Glycol | B |

| Freon – 11 | B | Freon – 12 | A |

| Freon – 113 | A | Fuel Oil | B |

| Gasoline | B | Glue | A |

| Glycerin | A | n-Hexane (50°C/122°F) | B |

| Hydraulic Oils | B | Hydrochloric Acid, 20% | B |

| Hydrogen | A | Isooctane (70°C/158°F) | B |

| Isopropyl Ether | B | Linseed Oil | B |

| Lubricating Oils | B | Magnesium Chloride Solutions | A |

| Magnesium Hydroxide Solutions | A | Mercury | A |

| Mineral Oil | A | Naphtha | B |

| Naphthalene | B | Oleic Acid | B |

| Palmitic Acid | A | Phosphoric Acid, 20%-70% | A |

| Potassium Hydroxide Solutions | B | SAE #10 Oil (70°C/158°F) | A |

| Seawater | A | Soap Solutions | A |

| Sodium Hydroxide, 20% | A | Sodium Hydroxide, 46% | B |

| Soybean Oil | B | Stearic Acid A | A |

| Sulfuric Acid, 5-10% | A | Sulfuric Acid, 10-50% | B-C |

| Tannic Acid, 10% | A | Tartaric Acid | A |

| Tricresyl Phosphate | B | Trisodium Phosphate Solutions | A |

| Tung Oil | B | Water (50°C/122°F) | A |

Typical Polyurethane Applications