Polyurethane Conveyor Rollers

Polyurethane Conveyor Rollers

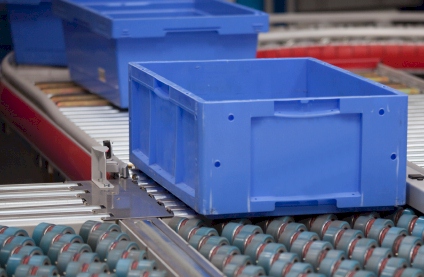

In packaging, production, and supply management processes, rollers are at the foundation of product, parts, and supply movement as a smooth and safe method for material transport. Sturdy and durable rollers produced by American Urethane can be found in many industries and supply operations. Our dependable and reliable production methods have made us a leader in the manufacture of roller products for diverse industries and a wide variety of applications.

A critical feature of American Urethane’s selection of polyurethane rollers is their ability to securely maintain the proper balance and grip on materials, regardless of their function. The grab and high traction benefit of our rollers are what places American Urethane rollers above our competition.

What are Urethane and Polyurethane Rollers?

Urethane rollers and polyurethane rollers are one of those tools that offer high and reliable performance but go unnoticed due to their efficiency. The process for the manufacture of rollers at American Urethane begins with the core, which can be aluminum or steel. The core is an essential part of our urethane rollers and is precision designed and engineered by our experienced staff of experts.

Once the core is selected it is carefully precision coated with polyurethane at the exact thickness and specifications required by the customer and their industry. An aspect of American Urethane’s production methods is the pride we take in producing urethane rollers that exactly meet the requirements and applications our customers need.

After a short curing time, the polyurethane adheres to its core. Unlike other coating materials, polyurethane does not require any finishing or buffing. At the end of the curing process, it is inspected, packed, and confirmed ready to ship. As a leader in the polyurethane roller manufacturing industry, American Urethane is proud of our product quality and ability to meet customer turnaround times.

Benefits of Urethane and Polyurethane Rollers

A benefit of polyurethane rollers is their durability and long service life. Every piece of equipment in a production operation has a limited-service life due to wear and constant use. It is a factor that producers understand and develop replacement plans to meet the expected need. In the case of American Urethane rollers, our customers have found that the rollers we supply last far longer than any others they have tried, which is a major reason we have such a highly respected reputation in the industry.

One of the reasons our urethane rollers are so long lasting is their exceptional resistance to abrasions caused by rough handling and harsh conditions. During hectic processing applications, workers are constantly in motion rapidly moving materials and placing loads and weight on urethane rollers. This continual use places stress on the rollers, which can lead to poor performance and damage. This is where American Urethane polyurethane rollers prove their quality and worth as a vital part of a procedure, application, or operation.

American Urethane takes pride in our ability to provide polyurethane rollers to meet the requirements of any environment. Our rollers are designed to endure any of the many extremes found in manufacturing conditions from places where there is extreme cold to ones where it is extremely hot. Polyurethane rollers from American Urethane can be used in freezers or hot houses and still provide our guaranteed excellent performance.

Why use Polyurethane Rollers?

To sell and supply urethane products in a competitive market, producers must ensure that what they produce is superior and can outperform the competition. As a high-quality manufacturer of polyurethane rollers and products, American Urethane has proven that our products meet and exceed customer expectations.

The market for urethane rollers is rapidly growing as they replace poor quality plastic, rubber, and metal rollers that do not have the same longevity and endurance of polyurethane. There are an endless number of uses for these resilient rollers from guide rollers to feed rollers as well as idler rollers and hourglass rollers.

American Urethane makes polyurethane rollers for dozens of industries and ships thousands of rollers every month. Every polyurethane roller is custom made to each client’s specification.

Industries Using Polyurethane Conveyor Rollers

• Automotive

• Bottling & Canning – Beer Assembly Lines

• Computer Chip Manufacturing

• Banking – Automated Teller Machines (ATM)

• Banking – Currency Counting Machines

• Elevator / Escalator

• Food Processing

• Health – Personal Hygiene Products Assembly

• Mining

• Product Manufacturing

• Product Packaging

• Printing industry

• Postal Service

• Video Rental Machines

• Vending Machines

Top Ten Reasons To Use Polyurethane Conveyor Rollers

1. Polyurethane Conveyor Rollers Offer Very Long Service Life Versus Plastic, Rubber & Steel Conveyor Rollers

2. Polyurethane Conveyor Rollers Provide Incredible Noise Abatement

3. Polyurethane Conveyor Rollers Offer Better Grab And High Traction For Paper, Glass, Wood, Etc.

4. Polyurethane Conveyor Rollers Are FDA Approved For Food Processing & Clean Rooms

5. Polyurethane Conveyor Rollers Strongly Resist Abrasion, Harsh Chemicals, Acids And Solvents

6. Polyurethane Conveyor Rollers Decrease Conveyor System Downtime

7. Polyurethane Conveyor Rollers Can Be Made In Any Color And Are Non-Marking

8. Polyurethane Conveyor Rollers Can Be Made Sponge-Soft Or Iron-Strong

9. Polyurethane Conveyor Rollers Can Handle Extreme Temperatures Both Hot And Cold

10. Polyurethane Conveyor Rollers Increase Profitability

View Other Industrial Applications Using Custom-Molded American Urethane Parts

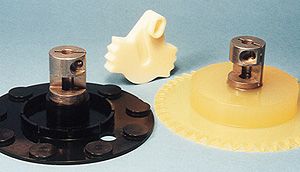

Examples Of Other Products Made By American Urethane

- Polyurethane Wheels

- Polyurethane Rollers

- Polyurethane Gears

- Polyurethane Bushings

- Polyurethane Bumpers

- Polyurethane Sprockets

- Polyurethane Trays

- Polyurethane Cradles

- Polyurethane Vacuum Chucks

- Polyurethane Casting / Molding

- Polyurethane Transmission Mounts

- Polyurethane Motor Shaft Couplings

- Polyurethane Belts

- Polyurethane Bearing Adapters

- Polyurethane Chucks

- Polyurethane Parts

- Non-Marking Polyurethane Wheel Covers

- Non-Marking Polyurethane Wheels

- Polyurethane Pipe Rollers

- Polyurethane Blade Clamps

- Polyurethane Handle Grips

- Polyurethane Escalator Wheels

- Polyurethane Elevator Tires

- Polyurethane Treads

- Polyurethane Military Thermoplastics