Polyurethane Wheels

Polyurethane Wheels

What is Polyurethane?

Polyurethane (PUR or PU) is a castable polymer class that is valued for its excellent wear resistance, easiness to use/mold, resistance to harsh environments (such as heat/acids/oil), high noise reduction properties, high abrasion resistance, and high-quality surface finish. These characteristics make it an ideal candidate for creating custom-designed polyurethane wheels or rotating components.

How are Polyurethane Wheels Used?�

Polyurethane wheels offer the elasticity of rubber wheels coupled with the strength and durability of metal wheels, making them an ideal choice for a wide range of applications, such as:

• Conveyor Belt Systems

• Chain Drive Systems

• Assembly Line Systems

• Drive Wheels

• Crown Wheels

• Guide Wheels

• Skateboard Wheels

• Caster Wheels

• Chair Casters

• Skate Wheels

• Pulley Wheels

• Dolly Wheels

• Swivel Wheels

• Railroad Wheels

• Rail Wheels

• Wagon Wheels

• Wheelchair Wheels

• Track Wheels

Benefits of Polyurethane Wheels

Polyurethane wheels offer a high degree of customization. Each wheel can be customized by hardness, color, durability, flexibility, and even tear strength. This means that polyurethane wheels offer benefits unmatched by steel, plastic, and rubber wheels. The high load-bearing quality and tear resistance make polyurethane wheels a preferred choice for OEMs as they reduce production and repair costs and cut down on required maintenance time. American Urethane has an expert team of designers and manufacturing engineers who can create custom polyurethane wheels that work for any purpose or application in short and long production runs. Some of the many benefits that polyurethane wheels offer include:

• A very long service life versus plastic, rubber, and steel wheels

• Incredible noise reduction

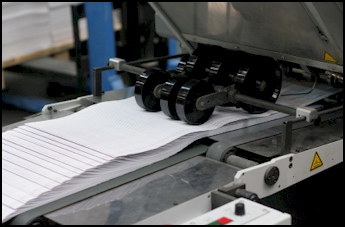

• Better grab and high traction for paper, glass, wood, etc.

• FDA approval for food processing and clean rooms

• Strong resistance to abrasion, harsh chemicals, acids, and solvents

• Decreased conveyor system downtime

• Customizable colors that are non-marking

• Customizable hardnesses, ranging from sponge-soft or iron-strong

• The ability to handle extreme temperatures, both hot and cold

• Increased profitability

Custom Polyurethane Wheels

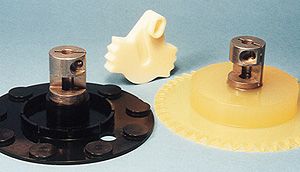

Polyurethane wheels can be made with or without the hub, recoated to your existing wheel or wheel hub, and even to repair an old wheel. The tooling costs for polyurethane wheel production and repair are much lower than those with metal, plastic, and other materials. American Urethane can create rapid polyurethane wheel prototypes at very affordable costs and high production rates, thus saving both time and money for our clients. All polyurethane wheels are non-marking and can therefore be used for sensitive drive belts in printing facilities or the food handling industry. For further information on any custom design requirements of polyurethane wheels in any number, contact American Urethane today!

View Other Industrial Applications Using Custom-Molded American Urethane Parts

Examples Of Other Products Made By American Urethane

- Polyurethane Wheels

- Polyurethane Rollers

- Polyurethane Gears

- Polyurethane Bushings

- Polyurethane Bumpers

- Polyurethane Sprockets

- Polyurethane Trays

- Polyurethane Cradles

- Polyurethane Vacuum Chucks

- Polyurethane Casting / Molding

- Polyurethane Transmission Mounts

- Polyurethane Motor Shaft Couplings

- Polyurethane Belts

- Polyurethane Bearing Adapters

- Polyurethane Chucks

- Polyurethane Parts

- Non-Marking Polyurethane Wheel Covers

- Non-Marking Polyurethane Wheels

- Polyurethane Pipe Rollers

- Polyurethane Blade Clamps

- Polyurethane Handle Grips

- Polyurethane Escalator Wheels

- Polyurethane Elevator Tires

- Polyurethane Treads

- Polyurethane Military Thermoplastics