Polyurethane Casting / Molding

Polyurethane Casting and Molding

Custom Molded and Castable Polyurethane Components

Custom Molded and Castable Polyurethane Components

Polyurethane molding / casting can is used by American Urethane to creates parts and components for all types of industries. These molded polyurethane components are available with fast prototype creation, low overall tooling costs and customized according to each client’s requirements.

For the production of high-quality thermoset products, polyurethane or urethane casting/molding is a fast low-cost method that offers exceptional tolerances with a wide variety of hardness, color, physical properties and chemical resistance. Polyurethane can be cast soft as rubber or as hard as nylon 6/6. Urethane parts offer long service life due to their superior physical properties.

Polyurethane is Superior To Plastic, Metal and Rubber

Polyurethane component parts are used because polyurethane is superior to other materials such as plastic, rubber and steel. Molded polyurethane parts offer high load and high compression abilities that function long after rubber and plastic parts have failed. With cast polyurethane parts can be made iron-strong or sponge-soft, in any color or shape. In addition polyurethane components offer long run durability and extreme resistance to harsh environments of heat, solvents, chemicals and abrasion.

Industries Using Molded Polyurethane Components:

- Material Handling

- Automotive After Market

- Military

- Corrugated box

- Chain Conveyor

- Elevator/Escalator

- Postal Service

- Food Processing FDA

- Computer Chip/ Robotics

- Medical & Surgical

- Bowling Industries

- Marine/ Maritime

- Power Transmission

- Mining & Drilling

- Seals/ Gaskets

- Industrial Cleaning

Case Study: Bottle and Canning Industry uses Molded Polyurethane Components

Millions of bottles and cans are created and processed in factories using cast and molded polyurethane components created by American Urethane. These polyurethane parts used in conveyor belt systems offer long service life, excellent grip strength and lower noise abatement to other materials. For bottling and canning this reduces downtime and downstream issues usually associated with lesser materials.

Product Engineers Prefer Polyurethane

Create Your Polyurethane Bumper Prototype Today

American Urethane is the premiere supplier of urethane parts and components for industries all over the world. We differentiate ourselves by providing the most rapid response possible to quotes and inquires. We offer very low tooling costs and rapid prototype creation. Best of all, when we respond to a quote, you are talking to an American Urethane engineer who understands your needs and concerns.

What is Urethane Casting?

The process for urethane casting, also known as polyurethane casting, begins with the formation of a mold which can be made from many different materials including aluminum, silicone, 3D printing and steel. The liquid urethane is cast into mold with a CNC urethane machine at 100°C/212°F temperature. The molds then move into a high temperature oven where the urethane hardens to a solid and then the part forms in the mold. The temperature and rate of flow, is closely monitored to ensure the highest quality of the final product.

Urethane casting is a fast, efficient, and inexpensive method for the production of durable and long-lasting parts. They can be produced in a variety of sizes with high tolerance precision. The polyurethane casting process allows for high quantity through continuous casting or low volume parts including R & D requirements.

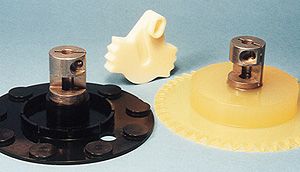

One of the added features of urethane casting is the ability to add threaded or other metal components during the casting process.

What is Polyurethane Molding?

Cast polyurethane, or urethane, (these terms mean the same thing) molding is typically a two component system of urethane and curative. The two components are heated, dynamically mixed together and cast into a heated mold. The two chemicals under heat crosslink and form a new stronger molecule now a thermoset compound.

This new thermoset compound is stronger than thermoplastics and rubbers because of the crosslinking. Once formed they can’t be melted back down, reground or used in any way in the production process again.

The continuous casting process can produce thousands of parts per day or a single mold can be filled to make one part only.

Urethane is a perfect material for molding since it can easily be adapted to any shape and form. It is also able to produce parts that are sturdy and rigid, or ones that are pliable and soft. These variations in the characteristics of polyurethane make it an ideal material for the production of strong, long lasting, and durable parts.

The polyurethane molding process is used for the production of high volumes of parts that can range into the tens of thousands. When large quantities are required and time is important, polyurethane molding is an excellent choice since it has the ability to produce thousands of parts per day with every part having exactly the same quality and tolerances.

Benefits of Polyurethane

Due to the fact that polyurethane is lightweight, has low production cost, and has exceptional physical properties, the polyurethane is adaptable to a variety of industrial uses. The urethane parts have noise abatement, chemical resistance, abrasion resistance, excellent cut and tear properties. Some of the many parts made with cast urethane are: gears, sprockets, bumpers, rollers, automotive mounts, seals and many more items.

One of the outstanding benefits of urethane is its ability to be custom designed to provide solutions for unique, unusual, and specialized manufacturing conditions. Parts can be produced that weigh a few grams or up to thousands of pounds. The only requirement is the submission and creation of the design to be produced.

Prototyping

Unlike other thermoplastic or rubber materials, thermoset polyurethane can easily generate a prototype from a CAD design. This one feature makes it possible to examine the final product before it goes into production and allows for making any necessary adjustments. Prototyping saves time, costs, and makes it possible to take a computer rendering and turn it into a useable part.

Regardless of the method used, products, parts, and components produced using polyurethane, or urethane, have the strength, endurance, and quality that are necessary attributes in today’s competitive market.

View Other Industrial Applications Using Custom-Molded American Urethane Parts

Examples Of Other Products Made By American Urethane

- Polyurethane Wheels

- Polyurethane Rollers

- Polyurethane Gears

- Polyurethane Bushings

- Polyurethane Bumpers

- Polyurethane Sprockets

- Polyurethane Trays

- Polyurethane Cradles

- Polyurethane Vacuum Chucks

- Polyurethane Casting / Molding

- Polyurethane Transmission Mounts

- Polyurethane Motor Shaft Couplings

- Polyurethane Belts

- Polyurethane Bearing Adapters

- Polyurethane Chucks

- Polyurethane Parts

- Non-Marking Polyurethane Wheel Covers

- Non-Marking Polyurethane Wheels

- Polyurethane Pipe Rollers

- Polyurethane Blade Clamps

- Polyurethane Handle Grips

- Polyurethane Escalator Wheels

- Polyurethane Elevator Tires

- Polyurethane Treads

- Polyurethane Military Thermoplastics