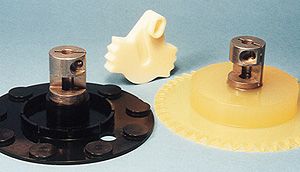

Polyurethane Motor Mounts

Polyurethane Motor Mounts

Mounts are the devices that anchor an object in its operating position. Not only do mounts control the transfer of noise and vibration, but they also work well in reducing flexing in critical components so wear and tear can be prevented. Polyurethane mounts are the best possible mounts to replace rubber factory mounts. With brilliant resistance to abrasion, these mounts can function well even under extreme automotive temperatures. These Mounts work well where extreme heat is not in close proximity to the urethane.

How are Polyurethane Mounts Manufactured?

The manufacturing of Polyurethane mounts at American Urethane takes place by following these simple steps:

Step 1: The molds that will be used to give the shape to the mount is prepared by a process called Master Molds. This is a low-cost tooling option that allows for short runs or large quantities.

Step 2: The polyurethane is then machined dispensed in liquid form into the molds in a conveyor oven heated to 250°F.

Step 3: The liquid urethane is then cured into a solid while in the 250°F oven.

Step 4: Once the polyurethane is cured completely, it is taken out of the mold and moved to post cure ovens at 250°F for 24 hours

Materials used by American Urethane to Manufacture Polyurethane Mounts:

As evident from the name, the primary material used by American Urethane to manufacture Polyurethane Mounts is “Polyurethane.” It is abbreviated as PU or PUR or shortened to urethane. Here are some important points about polyurethane that one must know:• Chemically, it is an organic polymer petroleum-based consisting of cross-linked molecules. This process is called thermoset cross linking. Once cross linked, they can’t be melted or ground for re use. This permanent cross linking is what gives the material superior physical properties over thermoplastic materials.

• All thermoset polyurethanes have maximum temperature range of 250°F so you must be aware of high heat compatibility.

• Polyurethanes have a lot of applications, such as the manufacturing of engine mounts, conveyors, bumpers and other industrial applications.

Features of Polyurethane Mounts

Polyurethane mounts have a lot of qualities that make them better as compared to rubber mounts. Here’s why Polyurethane mounts are preferred:

• The unique chemical composition allows it to be used in hot and cold working environments.

• They show excellent resistance to oil, coolants, grease, and most chemicals.

• Polyurethane mounts do not crack, and they last 3 to 4 times longer than rubber mounts.

• They offer easy customization and low tooling cost and give much longer service life versus rubber.

• Furthermore, these mounts are durable and are not easily deformed.

Polyurethane Mounts by American Urethane

Polyurethane mounts are one of the premium products of American Urethane. Prepared from the top-quality raw material, polyurethane urethane mounts are used by American Urethane in the form of the following products:

1. Polyurethane Transfer Mounts are employed to protect expensive drive trains by reducing their dangerous vibrations and bending. Resistant to oil, grease, and abrasion, these mounts last longer than rubber OEM mounts.

2. Polyurethane Exhaust Hangers: These devices are used by American Urethane as a better alternative for stock exhaust hangers made of rubber or steel because they provide great resistance to vibrations and road debris and can withstand extreme temperatures.

3. Motor Mounts: These mounts are used by American Urethane to provide a suitable stabilizer for the motor engines and prevent natural vibrations resulting from the internal combustion process.

4. Transmission Mounts isolate vibrations and are necessary to support the engine.

5. Body Mounts connect the frame of the vehicle to the body and absorb the driving noise and vibrations.

6. Frame Mounts provide excellent resistance to abrasion and are a reliable choice to provide breathing space to art.

7. Marine Motor Mounts: American Urethane uses these mounts specifically for marine vehicle engines to protect them from salt water with the high resistance to degradation.

8. Automotive Motor Mounts: Similar to motor mounts, these are specifically employed for automotive engine stabilization.

9. Poly Motor Mounts are used in a similar fashion to the motor mounts but are a better choice as compared to the rubber mounts.

10. Universal Motor Mounts: As their name explains, universal motor mounts offer all the combined qualities required from a standard mount.

11. Custom Motor Mounts: Here at American Urethane, custom motor mounts are also used in order to produce a flexible and compression resistant mount that can be adjusted by hardness according to the requirements.

View Other Industrial Applications Using Custom-Molded American Urethane Parts

Examples Of Other Products Made By American Urethane

- Polyurethane Wheels

- Polyurethane Rollers

- Polyurethane Gears

- Polyurethane Bushings

- Polyurethane Bumpers

- Polyurethane Sprockets

- Polyurethane Trays

- Polyurethane Cradles

- Polyurethane Vacuum Chucks

- Polyurethane Casting / Molding

- Polyurethane Transmission Mounts

- Polyurethane Motor Shaft Couplings

- Polyurethane Belts

- Polyurethane Bearing Adapters

- Polyurethane Chucks

- Polyurethane Parts

- Non-Marking Polyurethane Wheel Covers

- Non-Marking Polyurethane Wheels

- Polyurethane Pipe Rollers

- Polyurethane Blade Clamps

- Polyurethane Handle Grips

- Polyurethane Escalator Wheels

- Polyurethane Elevator Tires

- Polyurethane Treads

- Polyurethane Military Thermoplastics

LEARN MORE ABOUT URETHANE!

CONTACT AMERICAN URETHANE TODAY!

Polyurethane Mounts by American Urethane

Polyurethane mounts are one of the premium products of American Urethane. Prepared from the top-quality raw material, polyurethane urethane mounts are used by American Urethane in the form of the following products: